What does PETG mean

PETG, full English name

Poly (ethylene terephthalateco-1,4-cylclohexylenedimethylene

terephthalate)

It is a transparent and amorphous copolyester. The common comonomer of PETG is 1,4-cyclohexanedimethanol (CHDM), which is called polyethylene terephthalate-1,4-cyclohexanedimethylene. It is the product of ester exchange polycondensation of terephthalic acid (PTA), ethylene glycol (EG) and 1,4-cyclohexanedimethanol (CHDM). Compared with PET, it has more 1,4-cyclohexanedimethanol comonomer and more ethylene glycol comonomer than PCT. Therefore, the performance of PETG is very different from PET and PCT.

PETG sheet has outstanding toughness and high impact strength. Its impact strength is 3~10 times that of modified polyacrylate, and has a wide processing range, high mechanical strength and excellent flexibility. Compared with PVC, PETG sheet has high transparency, good luster, easy printing and environmental advantages.

PETG is an amorphous copolyester. In its production process, a certain amount of ethylene glycol is

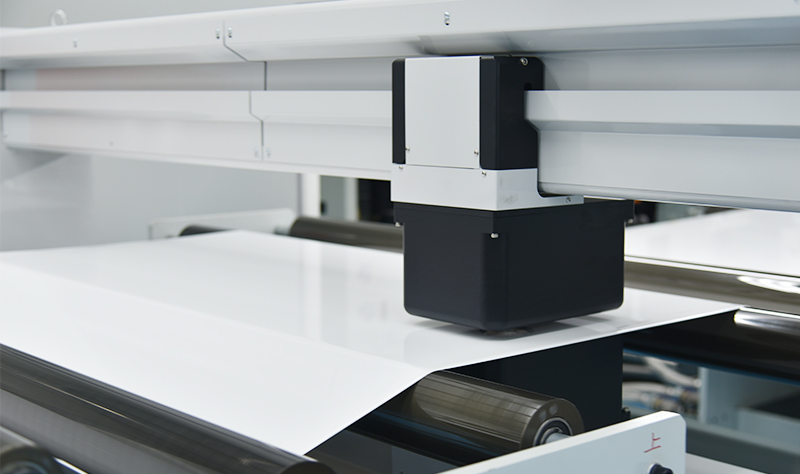

dimethanol (CHDM) can prevent crystallization, thereby improving processing and transparency. Its products are highly transparent and have excellent impact resistance, which is particularly suitable for forming thick wall transparent products. Its processing and molding performance is excellent. It can design any shape according to the designer's intention. It may use traditional molding methods such as extrusion, injection molding, blow molding, and blistering. It can be widely used in plates, sheets, high-performance shrink films, bottles, profiled materials and other markets. At the same time, its secondary processing performance is excellent, It can be modified by conventional machining.

So far, only two companies in the world, Eastman of the United States and SK of South Korea, have relatively mature technologies, Eastman PETG and SK of South Korea

The main domestic agents of PETG and other products include Shanghai Lianmo Chemical Co., Ltd. With the increase of CHDM in the copolymer, the melting point decreased, the glass transition temperature increased, and the crystallinity decreased, finally forming an amorphous polymer. Generally, the content of CHDM in PETG is 30% - 40%. It has good viscosity, transparency, color, chemical resistance and stress whitening resistance. It can be quickly thermoformed or extruded and blown. The viscosity is better than acrylic acid (acrylic).

PETG products are highly transparent and have good toughness, which is suitable for forming thick wall transparent products. PETG has excellent processing and molding performance, and can be designed in any shape according to the designer's intention. It can use traditional molding methods such as extrusion, injection molding, blow molding and blistering, and can be widely used in plates, sheets, high-performance shrink films, bottles and profiled materials, and other markets. At the same time, its secondary processing performance is excellent, It can also be used for conventional machining.

PETG sheet is easy to produce products with complex shape and large drawing ratio. Moreover, unlike PC board and impact modified acrylic, this kind of board does not need to be pre dried before hot forming. Compared with PC board or acrylic, it has shorter forming cycle, lower temperature and higher yield. PETG plates can be sawed, die cut, drilled, punched, sheared, riveted, milled and cold bent without breaking. Slight scratches on the surface can be eliminated with a hot-air gun. Solvent bonding is also a routine procedure. It is easier to process than general acrylic, impact resistant modified acrylic or PC board, and can be processed by flocking, electroplating, static electricity, etc.

Compared with foreign products with complete brand names, Chinese enterprises still have a lot to do in terms of catalyst improvement, polymerization conditions optimization, raw material recovery route optimization, product performance optimization, formula development, etc., and hope that more enterprises can join this field with large development space to lead the industry and promote industrial progress. PETG copolyester has broad development prospects in food, cosmetic packaging, medicine and health and other fields. It is time to develop PETG copolyester industry in China.

In recent years, some domestic enterprises have realized the industrial mass production of PETG through long-term scientific and technological research.

Analysis and forecast of China's PETG industry imports

With the continuous expansion of the demand of China's PETG industry, the import volume of China's PETG industry will continue to increase in the future. However, due to the rise of domestic substitution, the industry competition will further intensify, and it is expected that the import price of the industry will gradually decline in the future.

- Share

-

12

- 正在更新中...

- 正在更新中...